23/04/2020

Calenberg presents new railway product portfolio

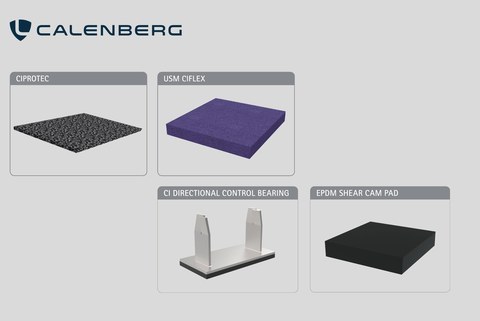

In addition to the already established track bed and sub-ballast mats of the USM and USM G type series as well as the microcellular EPDM Rail Pads and Base Plate Pads, Calenberg has further extended its product range for track technology.

Ciprotec is a PU-bound rubber granulate mat. It is primarily used on surfaces covered with ballast in railway track systems in structures such as bridges and tunnels to prevent ballast wear or protect structure layers in the interface between ballast and concrete or steel. Ciprotec can be lined with non-woven fabric or geotextile and supplied in different thicknesses or rigidities where required.

USM Ciflex is made of high-grade mixed-cell PUR foam and is manufactured in different thicknesses and densities, which have precisely determined physical characteristics. Thanks to its highly elastic behaviour, USM Ciflex is eminently suitable for reducing vibrations and structure-borne sound in track bed structures. USM Ciflex’s physical properties are tested by an independent body. The key advantages which USM Ciflex offers are permanent extreme flexibility, even under high stress loads, its excellent insulation properties and its precisely defined load ranges. USM Ciflex is versatile and can be used in both ballasted track systems and ballastless track or mass-spring systems and for all speeds and types of operation.

USM Ciflex is made of high-grade mixed-cell PUR foam and is manufactured in different thicknesses and densities, which have precisely determined physical characteristics. Thanks to its highly elastic behaviour, USM Ciflex is eminently suitable for reducing vibrations and structure-borne sound in track bed structures. USM Ciflex’s physical properties are tested by an independent body. The key advantages which USM Ciflex offers are permanent extreme flexibility, even under high stress loads, its excellent insulation properties and its precisely defined load ranges. USM Ciflex is versatile and can be used in both ballasted track systems and ballastless track or mass-spring systems and for all speeds and types of operation.The product range is further extended by directional control bearings and EPDM shear cam pads.

Directional control bearing is a special bearing for securing horizontal track alignment or absorption of horizontal forces in slab track systems. Delivered as stipulated on data sheet; differing project-specific dimensions may be available on request.

EPDM shear cam pad is a special bearing for the absorption of shear- and restraint forces in slab track systems. Can be supplied in dimensions adapted to the specific project requirements and in thicknesses of 5, 10, 12.5, 15 and 20 mm. The bearing has a load capacity up to 15 N/mm², depending on the format.

Calenberg is planning a gradual expansion of its product range in the coming years in order to meet the requirements of its customers.